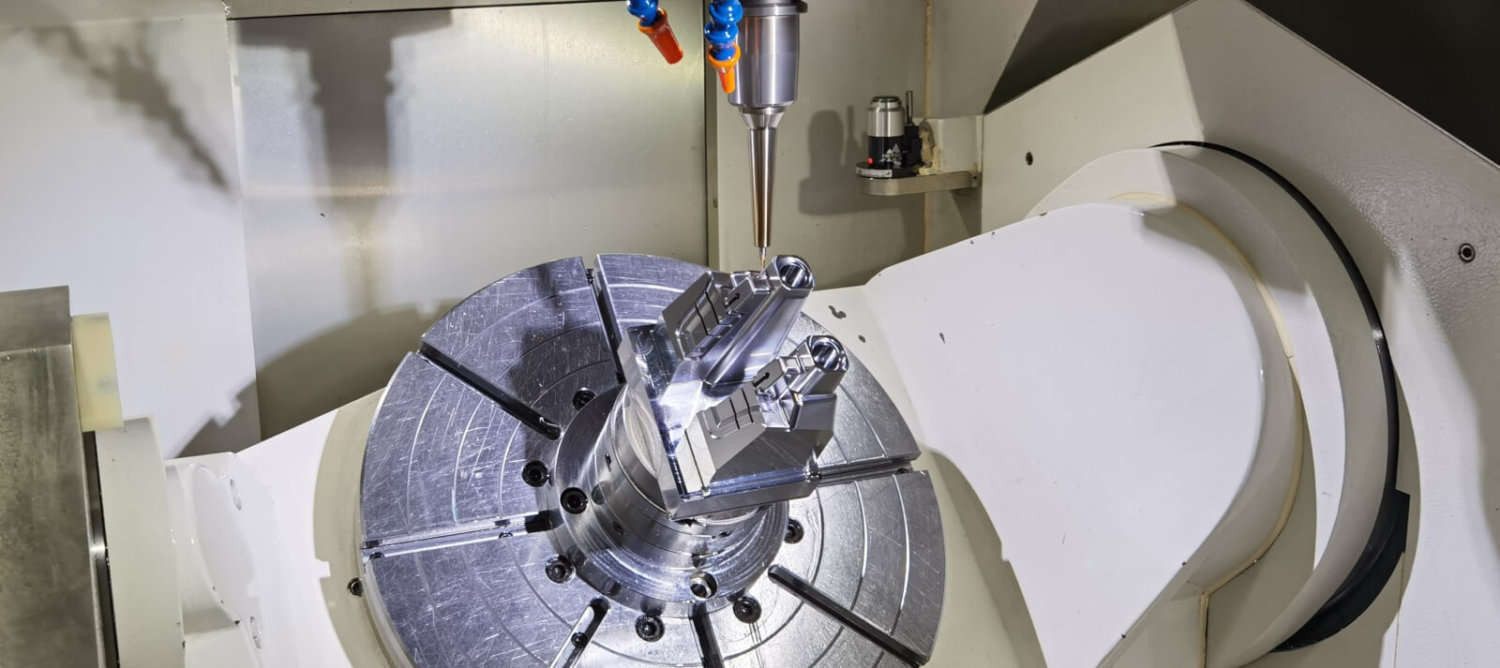

In recent years, China has emerged as a major player in the global manufacturing industry, offering competitive pricing and quality services for a wide range of products. Among these services is CNC machining, a process that involves using computer-controlled machines to manufacture complex parts, components, and equipment. If you are considering outsourcing CNC machining services to China, it is important to weigh the pros and cons and find the right company that can meet your needs.

Pros of Outsourcing CNC Machining to China

Cost savings – One of the primary reasons for outsourcing CNC machining services to China is cost savings. Due to lower labor costs and economies of scale, Chinese companies can often offer CNC machining services at significantly lower prices than their counterparts in other countries. Additionally, China has a well-established supply chain system that allows for the efficient sourcing of raw materials, further reducing costs.

Quality of service – Although the perception of Chinese manufacturing has been tarnished by reports of poor quality products, many companies in China offer high-quality CNC machining services. These companies often invest in state-of-the-art equipment, use advanced manufacturing techniques, and employ skilled workers to ensure the products they produce meet or exceed international quality standards.

Flexible production capabilities – Chinese companies that offer CNC machining services are often able to provide flexible production capabilities. This means they can handle both small-scale and large-scale manufacturing projects, as well as offer customized solutions tailored to the needs of their clients.

Cons of Outsourcing CNC Machining to China

Language barriers – While many Chinese companies that offer CNC machining services have English-speaking staff and documentation, language barriers may still be an issue. This can lead to misunderstandings or miscommunications that could impact the quality and timeliness of the completed project.

IP protection concerns – Intellectual property (IP) protection is a concern when outsourcing CNC machining services to China. Although China has taken steps to improve IP protection laws and enforcement, instances of IP theft and infringement remain a concern. It is important to work with a company that has strong IP protection policies in place and provides clear and transparent communication throughout the project.

Lead time – Due to the distance between China and many of its international clients, lead time may be longer than if the project were handled locally. This could impact the timeliness of delivery, which is especially important for clients with tight production schedules.

How to Find the Right CNC Machining Service Company in China

When looking for a company in China to handle your CNC machining project, it is important to do your due diligence to ensure you are working with a reputable and reliable partner. Here are some key factors to consider:

Experience – Look for a company that has a proven track record of providing high-quality CNC machining services. Check their website, reviews, and references to get a sense of their experience and capabilities.

Certifications – Ensure the company you choose is certified and compliant with relevant industry standards and regulations, such as ISO 9001:2015.

Communication – Effective communication is critical to the success of any CNC machining project. Make sure the company you choose has clear and transparent communication protocols in place and is able to communicate effectively in English or your preferred language.

IP protection policy – Choose a company that takes IP protection seriously and has strong policies in place to safeguard your intellectual property rights.

Location – While location is not a guarantee of quality, choosing a company in a region known for CNC machining expertise can be advantageous.

Conclusion

Outsourcing CNC machining services to China has its pros and cons. On the one hand, Chinese companies can offer cost savings, quality services, and flexible production capabilities. On the other hand, language barriers, IP protection concerns, and lead time may be a challenge. It is important to find the right company that can meet your needs and provide quality services while keeping communication transparent and protecting your intellectual property. With the right partner, outsourcing CNC machining services to China can be a successful business strategy.