| Prototype sheet metal parts | Precision Machining | Stainless steel turning parts |

| Rapid machining | Precision Machining Part | Stainless Steel Watch Case |

| Rapid prototyping cnc milling | Precision Machining Parts | Titanium Machining |

| Business Type | OEM& ODM Manufacturer (Custom CNC Machining Services) |

| Standard | JIS, ANSI |

| Products Range | Automobile parts,wind power generation equipment accessories,wind power generation equipment accessories, ER fluid, medical apparatus and instruments, standardization of custom, moto parts, machinery parts, lighting components, hardware accessories, electric motor products, etc |

| Agricultural machinery, electrical appliances, furniture hardware | |

| Materials | 1.Stainless Steel: SS201, SS303, SS304, SS316 etc. |

| 2.Carbon Steel: AISI 1045, 9SMnPb28 etc | |

| 3.Brass: C36000 (C26800), C37700 (HPb59), C38500(HPb58), C27200(CuZn37), C28000(CuZn40) etc. | |

| 4.Bronze:C51000, C52100, C54400, etc. | |

| 5.Iron:Grey iron and ductile iron | |

| 6.Aluminum:6061, 6063,7075,5052 etc. | |

| Machining: | cleaning, turning, milling, drilling, grinding |

| Main equipments | CNC lathe, cnc milling, stamping machine, |

| automatic lathe, grinder, thread rolling machine, tapping | |

| drilling machine, bending machine, etc | |

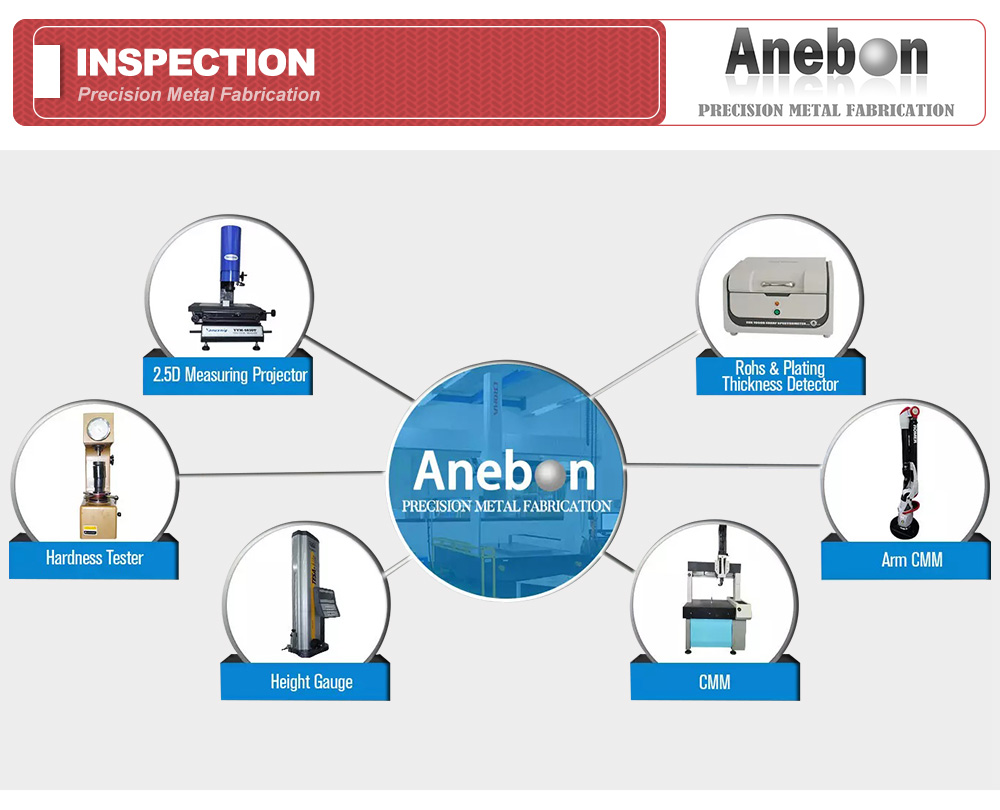

| Measuring & testing equipments | Profile Projector, Rockwell Hardness Tester, Vickers Hardness Tester, Roughness Tester, Salt Spray Test Machine, Micrometers, height gauge, etc. |

| Accuracy | Accuracy Of Machining:+/-0.005mm |

| Accuracy Of Grinding:+/-0.005mm | |

| Surface Roughness:Ra0.8 | |

| Parallelism:+/-0.005mm | |

| Verticality:+/-0.005mm | |

| Concentricity:0.003mm | |

| Surface Treatment: | Polishing, Deburring, Chrom Plate, Ni Plated, Zine plated, Silver platinng |

| Clear anodizing, Anodizing black, Carburizing Nitriding, Heat Treatment, etc... | |

| MOQ | 1 Pcs. Depending on detailed orders. Accept order for small batches. |

| DRW Format | DWG, PDF, IGS, STEP, SLDPRT, SLDDRW, PRT, DRW, DXF, X_T, etc... |

| QC System | 100% Inspection before shipment |

| Certificate | ISO9001: 2015,SGS Factory Audit |

| Payment Term | 50%T/T+50%T |

| Lead time | 12~45 days after confirming |

| Sample Lead Time | 10-15 Working Days. |

| Transport Package | Full consideration of practical situation: foam/wooden box, anti-rust paper, small box and carton, etc. |

| Our Advantages | Reliable Quality |

| Competitive Price | |

| High precision, high quality, tight tolerance | |

| Continuous Improvement | |

| Defect-Free Products | |

| On-Time Delivery | |

| Customer Satisfaction | |

| Excellent After-Sales Service |

.jpg)